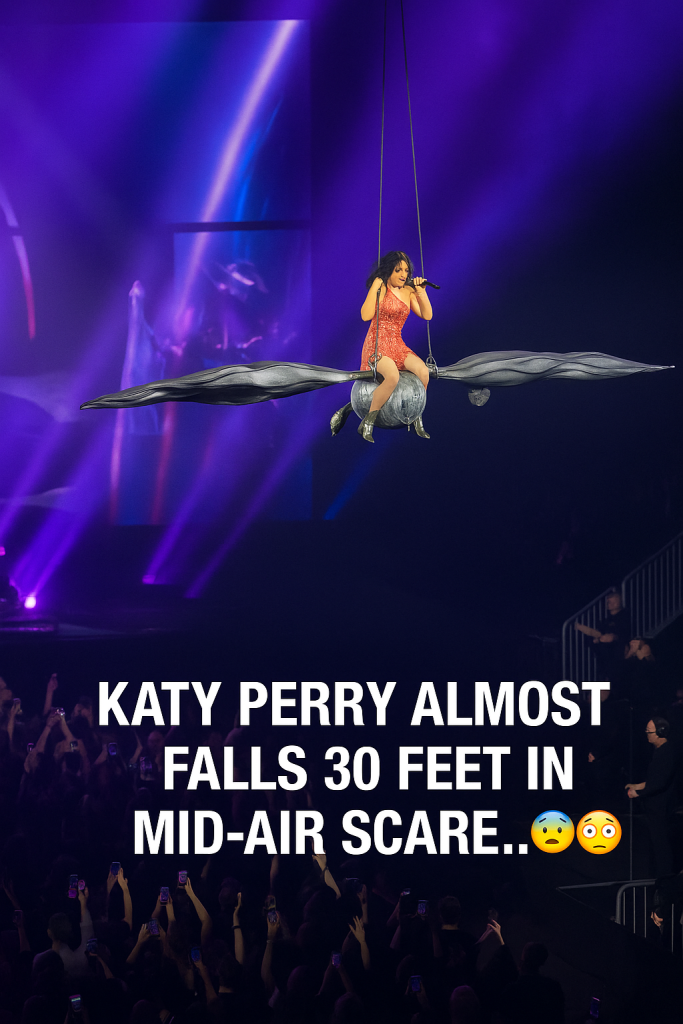

In a harrowing incident that underscores the critical importance of safety protocols, a woman narrowly avoided a catastrophic 30-foot fall due to a sudden technical malfunction. The distressing event unfolded recently when a piece of equipment malfunctioned during what should have been a routine situation, turning into a close call that captured widespread attention online.

The incident occurred when the woman was engaged in an activity involving elevated height — reports indicate she was either working on a platform, climbing, or using an elevator-like machinery. Suddenly, a technical error in the support system triggered a near-fall scenario, putting her at immediate risk of plummeting approximately 30 feet to the ground below.

Experts analyzing the situation believe the malfunction involved a failure in the mechanical or electronic safety mechanisms designed to hold or secure her safely. Such systems often include harness locks, automated brakes, and load-bearing sensors that work in concert to prevent falls. In this instance, one or more of these components did not function as intended, creating a terrifying moment that could have led to severe injury or worse.

Fortunately, thanks to quick reflexes and emergency backup features, the woman was able to hold on or was caught just in time before a full fall happened. Emergency responders and colleagues swiftly arrived on the scene to assist and ensure her safety, preventing what could have been a tragic accident.

While detailed information about the exact location and nature of the equipment involved has not been disclosed, this incident has sparked a wave of concern and calls for stricter safety standards and regular maintenance checks on all machinery and structures where similar risks exist.

Industry specialists stress that near-misses like this one should be treated as urgent warnings. Mechanical and software systems, especially those responsible for human safety at heights, must undergo rigorous testing and continuous monitoring. Experts recommend implementing redundant safety mechanisms and fail-safes to catch any potential hazards before they escalate.

In addition to the technical lessons learned, the incident serves as a reminder for individuals working at heights to always use personal protective equipment and remain vigilant, even when relying on technology that appears foolproof.

Social media users have responded strongly to the viral footage and accounts of the event, expressing sympathy for the woman and outrage over the equipment failure. Comments stress the need for accountability from manufacturers and employers alike to prevent anything similar from occurring again.

With investigations reportedly underway, safety authorities and technical inspectors are now reviewing the equipment’s design, maintenance history, and operational protocols to pinpoint the failure’s root cause. Their findings will likely inform updated regulations and improvements across industries utilizing similar technology.

This close call is a stark illustration of how quickly everyday situations can become dangerous when safety systems falter, and highlights the ongoing need for vigilance, advanced engineering, and robust safety cultures in all environments where people are exposed to fall hazards.