In a groundbreaking study, researchers have discovered an innovative method to recover precious metals from electronic waste (e-waste) by heating electronics to a staggering 3,000°C using an electrical current. This remarkable technique allows for the extraction of valuable metals without generating hazardous waste.

The research indicates that utilizing e-waste as a source for precious metals could be up to 13 times more cost-effective than traditional mining practices. Traditionally, recovering metals from broken electronics has involved high-energy processes that often release toxic emissions into the atmosphere. However, the new method, known as “flash joule heating,” is significantly more energy-efficient, boasting an efficiency increase of 80 to 500 times.

A fascinating 2008 study revealed that one ton of mobile phones, excluding batteries, can yield approximately 130 kg of copper, 3.5 kg of silver, 340 grams of gold, and 140 grams of palladium. These impressive quantities would be considered exceptional if evaluated in a mining context, ranking in the 99th percentile for quality.

In comparison, conventional open-pit mining operations typically extract gold at rates of 0.5 to 1.8 grams per ton and silver at 100 to 180 grams per ton. With an astonishing 40 million tons of e-waste generated each year, it’s clear that there is tremendous potential in what scientists refer to as “urban mining,” the process of harvesting metals from discarded electronics.

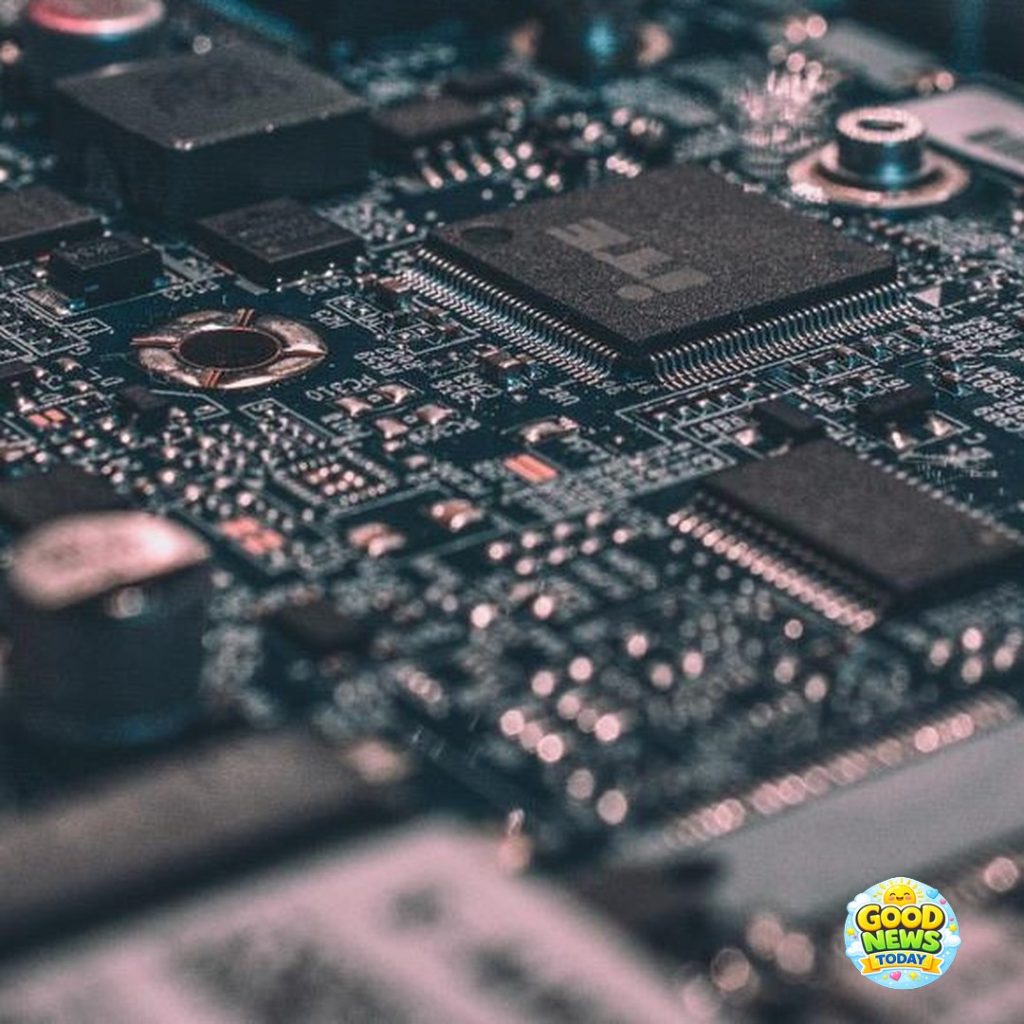

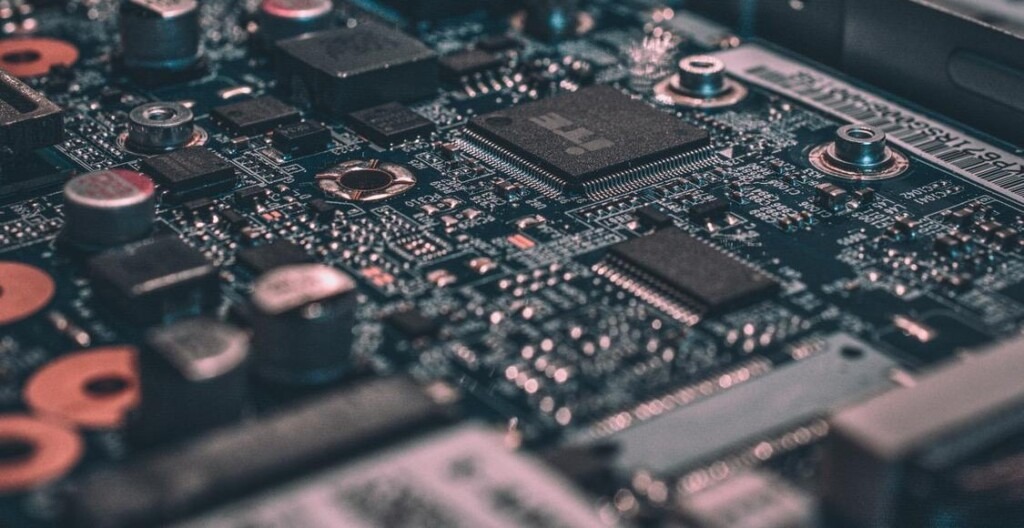

Researchers at Rice University conducted experiments by shredding printed circuit boards and combining them with carbon black to enhance conductivity. Inside the flash joule chamber, the applied electrical current is so intense that precious metals such as rhodium, copper, and gold vaporize, while the carbon-based components, like plastics, undergo carbonization. This same innovative approach has even been utilized to transform plastic into diamonds!

In the realm of metal recovery, mining companies often employ patented methods to separate gold, zinc, or nickel from their ore. Similarly, additives play a crucial role in enhancing the recovery rates of vaporized metals, with halides or fluorine compounds boosting rhodium recovery to over 80% and palladium recovery to 70%. Chlorine-based substances, like bleach, have also proven effective, achieving silver recovery rates exceeding 80%.

As the prices of these precious metals continue to soar, finding new and affordable sources is essential for maintaining competitiveness across key industries. This exciting development in urban mining not only promises a sustainable solution for metal recovery but also paves the way for a greener future.

Feel free to share this inspiring concept of urban mining with your friends!