A malfunctioning motor can halt production in an automated factory, but thanks to recent advancements, it may soon be possible to create a replacement motor right on-site, significantly reducing downtime and costs.

On Wednesday, MIT researchers unveiled an innovative multi-material 3D-printing platform capable of fully fabricating electric machines in a single step, with materials costing as little as 50 cents. This groundbreaking system allowed them to produce a fully 3D-printed electric linear motor in just a few hours, utilizing five different materials. Remarkably, the motor only required one post-processing step to become operational.

The performance of this newly assembled device matched or even surpassed that of traditional motors, which often involve more complicated manufacturing processes and additional finishing steps.

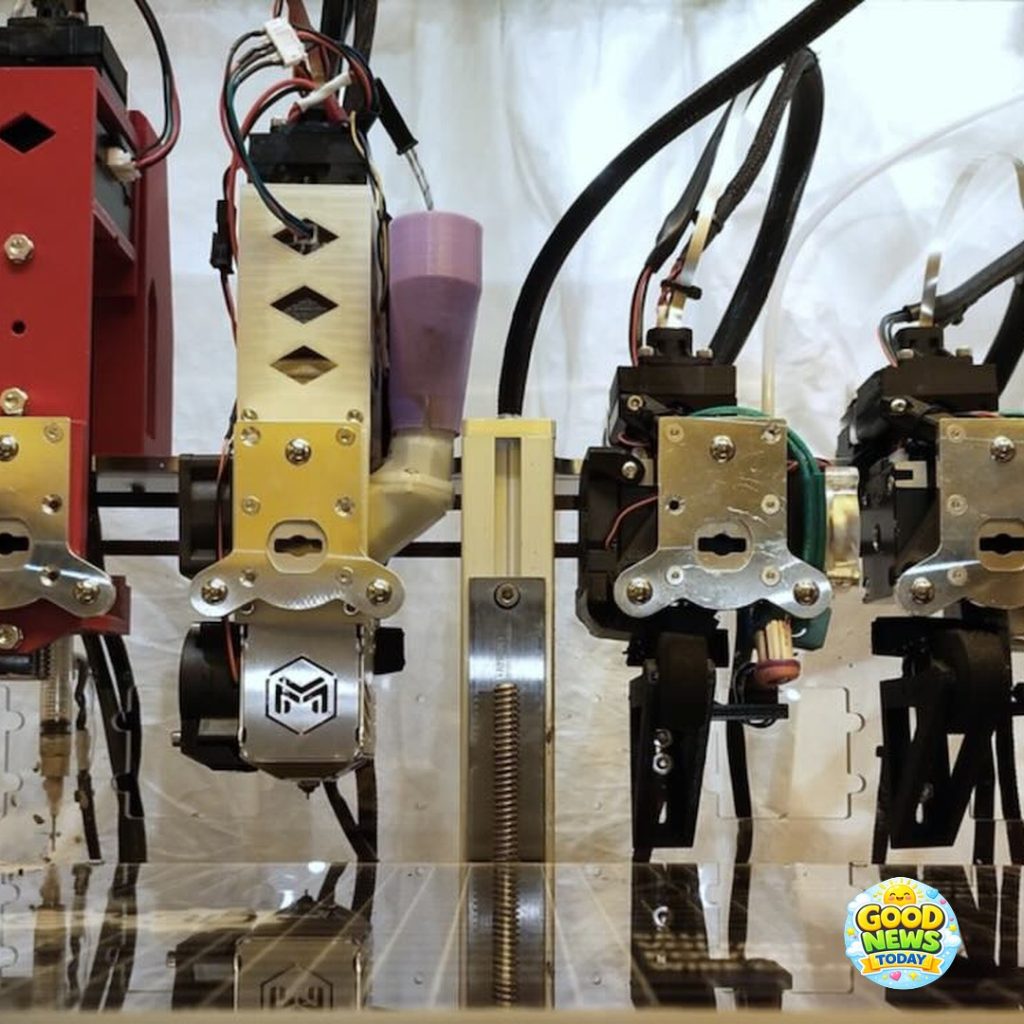

This advanced system can process a variety of functional materials, including those that are electrically conductive and magnetic, by utilizing four extrusion tools. Each tool manages different forms of materials, allowing the printer to layer them effectively as it builds the device from the ground up.

In the future, this 3D printing technology has the potential to swiftly produce customizable electronic components for robots, vehicles, and medical devices, all while minimizing waste.

“This is a remarkable achievement, but it’s just the beginning. We have the chance to revolutionize manufacturing by creating hardware on-site in a single step, reducing our dependence on a global supply chain. Our demonstration shows that this is entirely achievable,” expressed Luis Fernando Velásquez-García from MIT’s Microsystems Technology Laboratories, who is the lead author of a paper detailing the 3D-printing platform.

To manufacture an electric machine, the researchers needed to seamlessly switch between materials with different functions. For instance, the device required an electrically conductive material to facilitate electric current and robust magnetic materials to create magnetic fields for effective energy conversion.

While most multi-material extrusion 3D printing systems can only alternate between two materials of the same type, the researchers ingeniously modified an existing printer by adding four extruders, each capable of processing a different type of feedstock.

Each extruder was meticulously designed to meet the specific needs and limitations of the materials. For example, the electrically conductive material had to harden without excessive heat or UV light, which could damage the dielectric material. Meanwhile, the highest-performing conductive materials are typically available as inks, which are extruded through a pressure system, necessitating diverse requirements for each material used.